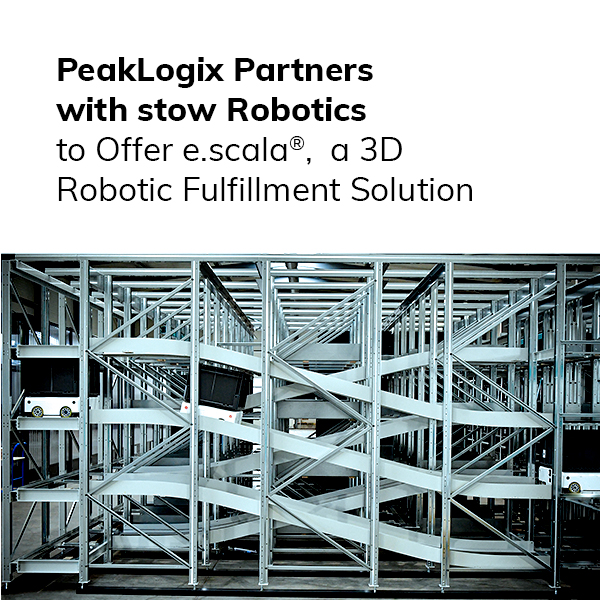

Supply chain integration partner PeakLogix, an Alta Material Handling company, has announced a strategic partnership with Movu Robotics, a global leader in warehouse automation solutions that stands out by bringing easier logistics automation technologies to the world's warehouses. This partnership means Movu Robotics and PeakLogix can offer the benefits of Movu's plug-and-play robotics portfolio as part of their solutions for…

View Author Page of Sara Yezzi

Sara YezziMarch 4, 2024