At PeakLogix, many of the integrations we’ve completed over the years have fed corrugated boxes to a baler as part of a facility’s recycling operations. Recently, we were asked if a compactor could achieve the same outcome. In short, compactors are used for disposing of waste, while balers are more appropriate for recycling processes.

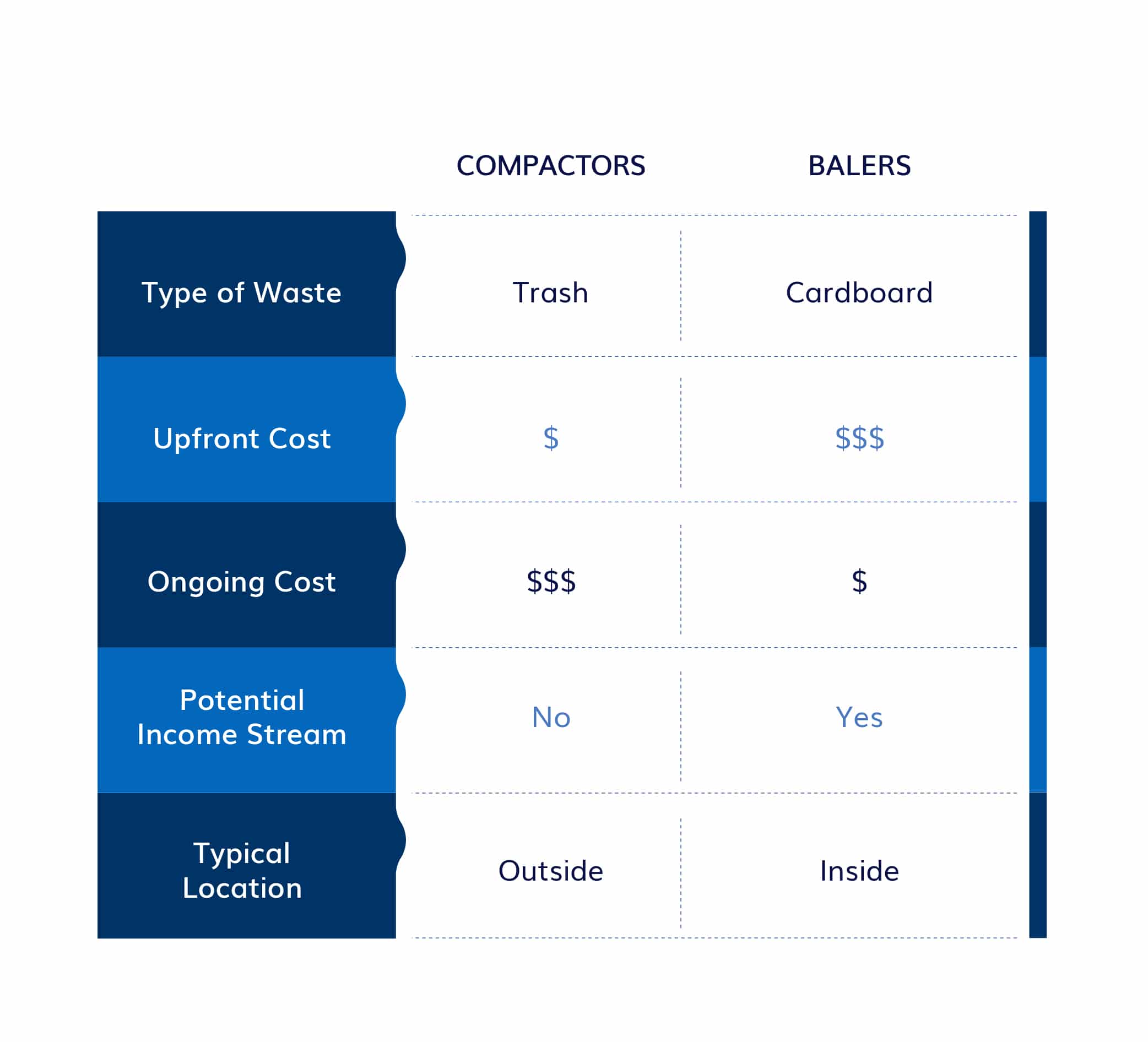

Here’s a quick summary of the difference.

Compactors

The purpose of compactors is to condense all forms of waste – everything from trash to cardboard to wood – into a single container before it’s hauled away for disposal. While condensing it reduces the number of container hauls needed to dispose of the waste, it’s how many facilities manage their waste but not how they manage their recycling.

Customers buy or lease the compactor/container, then hire a disposal company to manage their hauls. There are associated costs – equipment fees, hauling fees, etc. Some facilities have multiple container hauls per day, and the costs to manage waste can get expensive. Some companies have dedicated compactors for cardboard – however, they still aren’t taking advantage of the value because the cardboard isn’t baled.

Advantages of using a compactor include:

- The effective management of various types of material waste.

- An inexpensive option to both purchase and integrate into operations.

- The versatility to save space in a facility by placing the compactor outside.

Disadvantages of using a compactor include:

- The recurring cost of handling and hauling waste.

- The loss of the potential income stream that recycling provides.

Balers

Balers are recycling machines (not disposal machines). Customers use them to process their recyclables – anything from cardboard, paper, plastics, non-ferrous metals, etc. In distribution centers, balers are used for cardboard and plastic (stretch film), and provide an efficient mechanism for managing and processing cardboard into the baled form necessary for selling it.

Facilities will either purchase balers outright or broker/lease them for a specific period of time. Paper brokers and/or recyclers partner with distribution centers and other facilities to provide the best price for their baled recyclables. They also handle the logistics of storing and transporting it. Some DCs can earn significant revenue, up to hundreds of thousands of dollars, for their recycled cardboard (depending on the value of the material at that time).

The advantages of balers are:

- Balers are generally considered “green” – they are a key component in the recycling movement and reducing the amount of waste added to landfills.

- Balers allow customers to earn revenue on their cardboard, which can be a significant revenue stream.

The disadvantages of balers are:

- Balers can be expensive to purchase – new horizontal balers can range from $70,000 to over $200,000 (depending on size, speed, automatic tying, etc.).

- Balers are usually inside a facility and take up valuable floor space.