The client was investing significant labor to manually palletize and transport its product, and required a new system to receive up to 60 cases/minute from each of 2 production lines, then build pallets with the top layer inverted.

Efficiencies created using robotic palletizers and automated conveyor

The client was able to significantly increase their productivity while eliminating manual labor using robotic palletizers and automated conveyor.

The solution

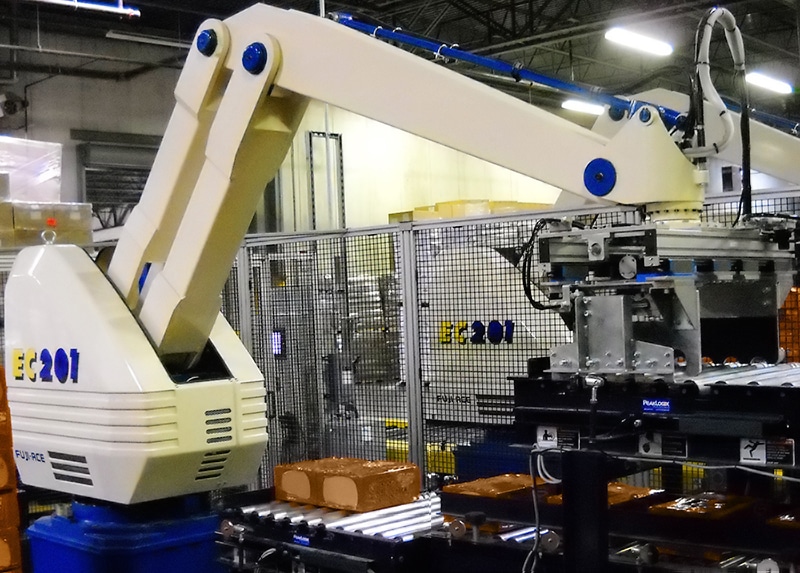

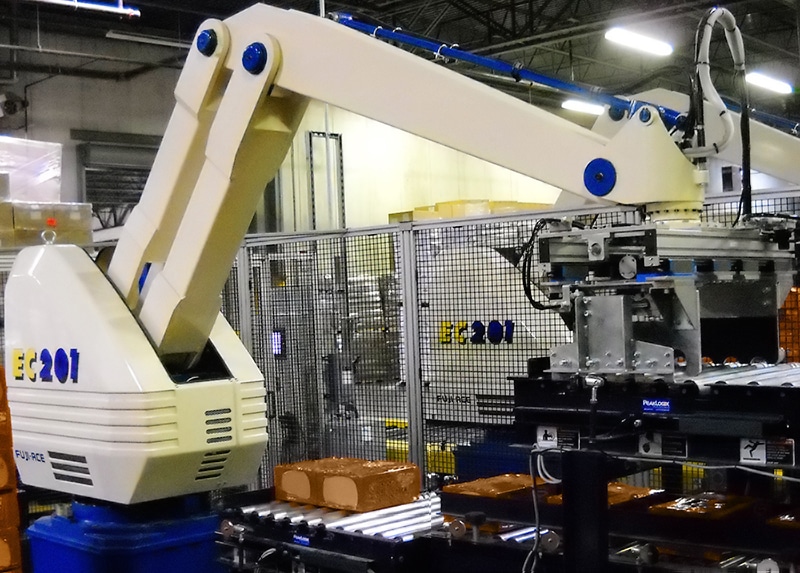

PeakLogix designed and installed an automated conveyor system to feed cases into and transport pallets out of 4 Fuji Robotic Palletizers, integrating robots and custom-built end effectors.

The results

An automated solution eliminated the need for manual labor

The new system eliminated all manual labor and has the capacity to palletize up to 120,000 cases into 600 palletized loads in a single 20-hour day.