Robotic palletizers can eliminate the need for manual labor while achieving a rate of better than 100,000 cases over 20 hours. Combined with a robust WMS, automating the process of stacking product onto pallets allows for real-time feedback and system optimization.

Robotic palletizing increases the accuracy, consistency, and efficiency of your palletizing operations. The increased rate and 24/7 operations yield obvious production benefits.

By layering product accurately and consistently, you can also realize more compact pallets that save space in your warehouse and trailers, helping to optimize your floor plan and lower your freight charges.

Robotic palletizers excel at product that conventional palletizers struggle with, including heavy bags and pails, and with the right End of Arm Tooling (EoAT), they can even handle the most awkward slip sheets.

Robotic palletizing helps optimize material handling workflows.

Robotic palletizers increase the consistency of operational costs, improve morale in the workforce, and allow you to allocate staff to more profit-driven, value-adding tasks.

Especially late in a shift, manual labor is known to struggle with both quality and speed – and that’s not an indictment of your personnel. People simply get tired and they suffer from overuse injuries and boredom.

In high throughput facilities running multiple shifts per day, robotic palletizers are an important step in streamlining processes to maximize efficiency.

Robotic palletizers increase optimization across facilities.

Robotic palletizers can reduce or eliminate manual labor associated with palletizing, enable production lines to run nearly continuously, and stack freight with exacting precision.

With the appropriate end of arm tooling, robotic palletizers can cost-effectively handle dunnage, slip sheets, and inverted layers, and excel at product that conventional palletizers struggle with such as bags and pails.

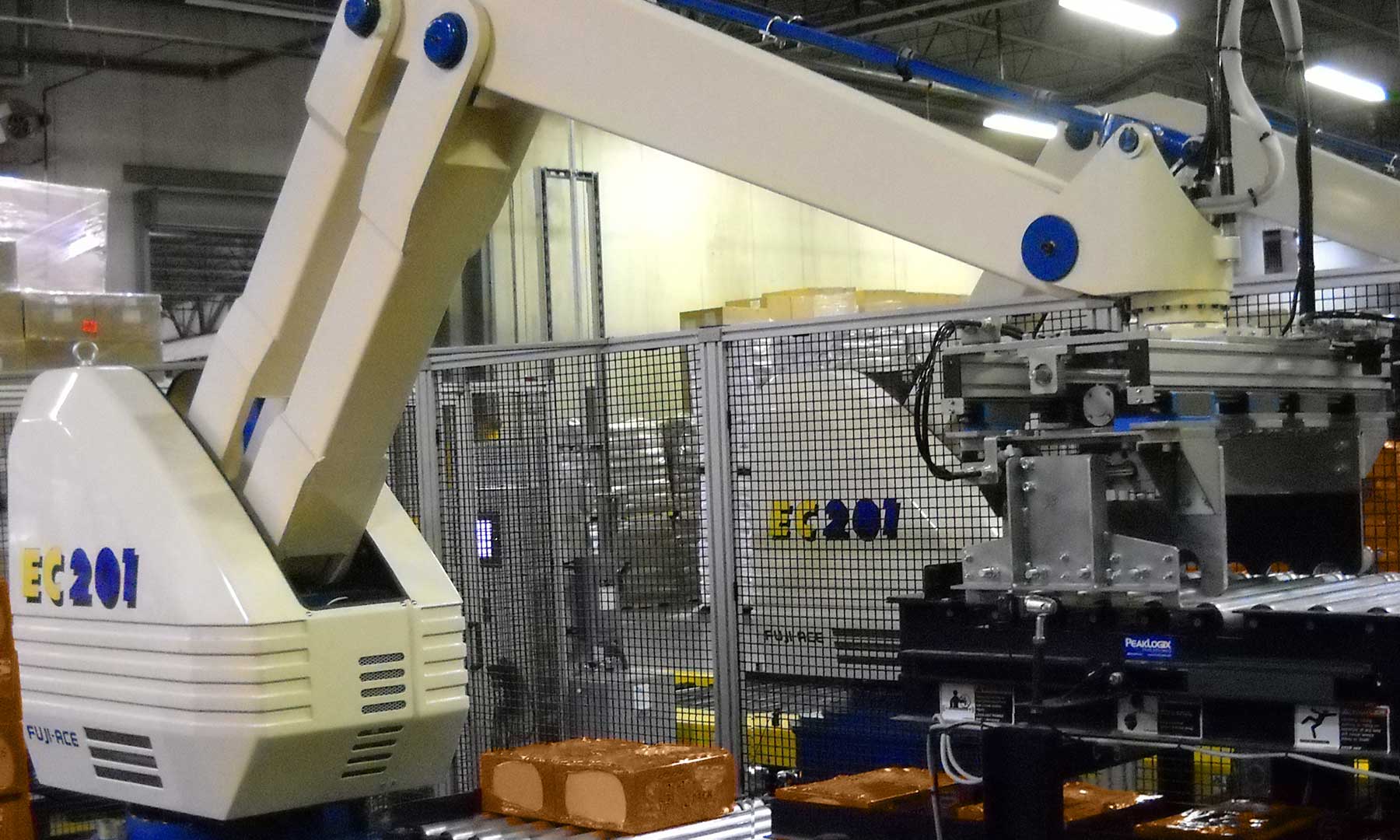

The Fuji Robotics EC-201 can achieve 1600 cycles/hour, interlocking 25-kg bags. Multi-Pickup, 2-in-2-out Palletizers can lift and stack multiple products at the same time, from multiple infeed conveyors.

1,600

CYCLES/HOUR

120K

CASES PER DAY

Custom robotic palletizer integration by PeakLogix.

Robotic palletizers help streamline the workflow and normalize operational costs in a number of important ways.

- Predictable, consistent speeds not just over the course of a shift, but over the course of the entire day

- Eliminate manual labor at injury-prone tasks, increasing morale and decreasing turnover

- Provide exact accuracy of layers, maximizing pallet density as well as the cubic space of your warehouse and trailers

- Equipped with a variety of EoATs to handle dunnage, boxes, totes, bags, and buckets

- Designed to be sensitive to pressure, guaranteeing that products aren’t smashed or damaged

- Increase customer satisfaction by helping to ensure the quality of the product delivered to the end-user

- Operate where it can be difficult or dangerous, including hot, cold, and dusty environments

- Don’t take sick leave or vacation time, and have flexible maintenance, helping to keep budgets balanced

Your facility is better with a customized robotic palletizer solution from PeakLogix.

While conventional palletizers have some advantages when dealing with high volumes of the same product — such as many manufacturing facilities — robotic palletizers allow facilities to more efficiently handle different sized or shaped product.

An omnichannel ecommerce store dealing with multiple products from multiple vendors can use a robotic palletizer that can individually select each item from an infeed conveyor, rotate the item to the proper orientation, and place it in exactly the right place cycle after cycle.

By switching out the EoAT, the same line can run vastly different products, from small cartons to large, heavy bags.

We have a robotic palletizing solution for you.

We are the only robotic palletizing solutions provider to give you valuable insight into your projected growth using a custom integration. Our top priority is your success, so the equipment brand or manufacturer comes second to the solution design unless you prefer a specific OEM. Our offerings are within reach no matter where you are.

Are you ready to integrate robotic palletizers?

Schedule a consultation.

Contact us today for a tailored solution to scale your business using a solution built on the metrics and data we obtain. Schedule your obligation-free consultation now.